CASE STUDIES

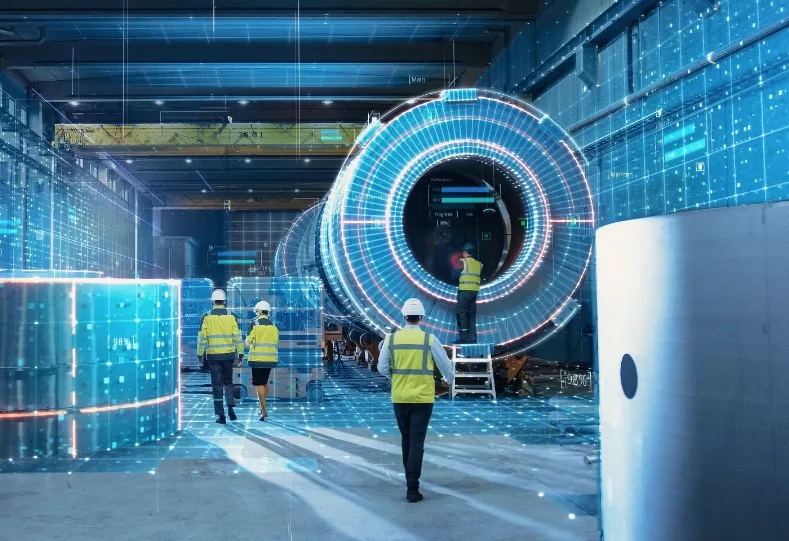

Step with us into the realm of the real-world applications and successes that have enabled us to lead data asset digitisation in heavy industries such as Oil and Gas, Power, Mining, Renewables, Infrastructure and Commercial Buildings. Each case study explores a challenge, innovation, and triumph, providing insights into the demonstrable impact of our work. From enhancing operational efficiency to enabling smarter decision-making, these stories illustrate the transformative power of DIGATEX’s expertise.

Merging companies means merging data

Our client, an international oil and gas operator, faced a major challenge following a spate of mergers and acquisitions. The company inherited new assets with disparate coding systems and poor-quality data, leading to inefficiencies in information sharing and material management. This situation was causing increased costs and threatening to reduce facility uptime and impacting on production capabilities.

Bringing Digital Twins to life in the Gulf of Mexico

Building digital twins for its existing facilities in the Gulf of Mexico meant extracting and reverse engineering a huge amount of content from their legacy documents. A key challenge was transforming data from 60,000 legacy documents into a usable format for the digital twin platform. This involved extracting and classifying detailed content, including tags and design data attributes, a process critical for the accurate development of a master tag register.

Improving Master Data Management for a GCC Operator

Our client needed to improve their master data management by aligning engineering data, at the Functional Location (FLOC) level within their SAP Maintenance System, with supporting engineering data in their Document Management System. However, achieving this was handicapped by in-house engineering updates in the Document Management Systems, which were not reflected in the maintenance system. This led to inconsistencies and errors during maintenance tasks.

Enhancing Maintenance for Specialist Engineering company

Our client, a Technical Consulting Services (TCS) specialist, provides maintenance engineering services to the Oil and Gas markets. A critical initial task in their contracts is to create a Maintenance Hierarchy, which organises all maintainable equipment and materials. This process traditionally involved manually extracting hundreds of thousands of engineering tags from unstructured sources, which is a time-consuming and costly exercise.

De-risking Asset Shutdown

During the critical shutdown and maintenance planning, our client identified a Vibration Cable as a crucial component that needed to be replaced. However, there was a significant hurdle – the cable was not in the client’s inventory and vendors were quoting a daunting 20-week lead time.

Consistency and Accuracy for a Gas Facility

In the aftermath of the Iraq War, Wood Group was tasked with bringing a Gas Facility back online, including war damage upgrades. A significant challenge was the lack of consistent Tag Numbering across the site. Different contractors had maintained the facility over time, resulting in varied tag codes for the same units and drawings. This posed a major risk for an asset reliant on a Master Tag Register.

Unlocking the Value of Petronas’ Engineering Data

In 2019 Petronas set DIGATEX a big challenge: Compare more than 500,000 as-built hand marked up isometric drawings used by the mechanical completion and commissioning teams to the CAD generated drawings. Map all the flanges between these drawings, check and correct differences and generate a composite flange register with consistent flange ID numbers. We completed this in 7 months and then went on to perform similar tasks across their fleet of assets, bringing in all the torquing and gasket data from the various inspection reports.

Enhancing Shutdown Management for O&G Operator

Our client needed a specific valve that was crucial for their planned shutdown, but the best available delivery slot window for this valve was threatening the scheduled startup of the facility, posing a major commercial risk as a result of the inevitable operational delays that would follow if a valve could not be found sooner.

start THE conversation

Inspired by the success stories

in our case studies?

These narratives are just a glimpse of what DIGATEX can achieve for your organisation. If you’re ready to explore how our innovative solutions can address your unique challenges, we’re here to embark on that journey with you. Connect with us to discuss how our expertise in asset data digitisation can drive efficiency, accuracy and growth in your operations.